Diode laser machines are really useful tools. People use them in lots of areas. This includes factory work on materials, dental treatments, beauty procedures, and physical therapy. In beauty treatments, they have truly transformed hair removal and skin improvement. They give safe, exact, and strong results. Engineers and designers who create or adjust these systems need to understand what affects diode laser performance. This helps them build machines that are reliable, efficient, and effective.

Three main factors set the performance and efficiency of any diode laser system. These are power output, wavelength, and cooling design. The factors connect to one another. They also directly influence how stable the machine is, how easy it is to use, and how long it lasts.

At the center of a diode laser is its semiconductor p-n junction. When the right voltage is applied, electrons and holes join together. They release energy in the form of photons. This is known as electroluminescence. The photons get boosted inside an optical cavity. This creates a coherent laser beam. How precise and effective this works depends a lot on choices made for power, wavelength adjustment, and heat control.

Key Factors in High-Performance Diode Laser Machines

Putting laser diodes into working machines goes beyond simply choosing a diode. It means coordinating drivers, optics, and heat control solutions. All this ensures the system runs at its best. Every factor—wavelength, power output, and cooling design—has a big role. They decide the machine’s efficiency, accuracy in treatments, and durability over time.

波长

The wavelength comes from the bandgap energy in the semiconductor material. Engineers can change the blend of compound semiconductors like GaAs or InGaAsP. This allows them to set the emission wavelength to fit certain needs.

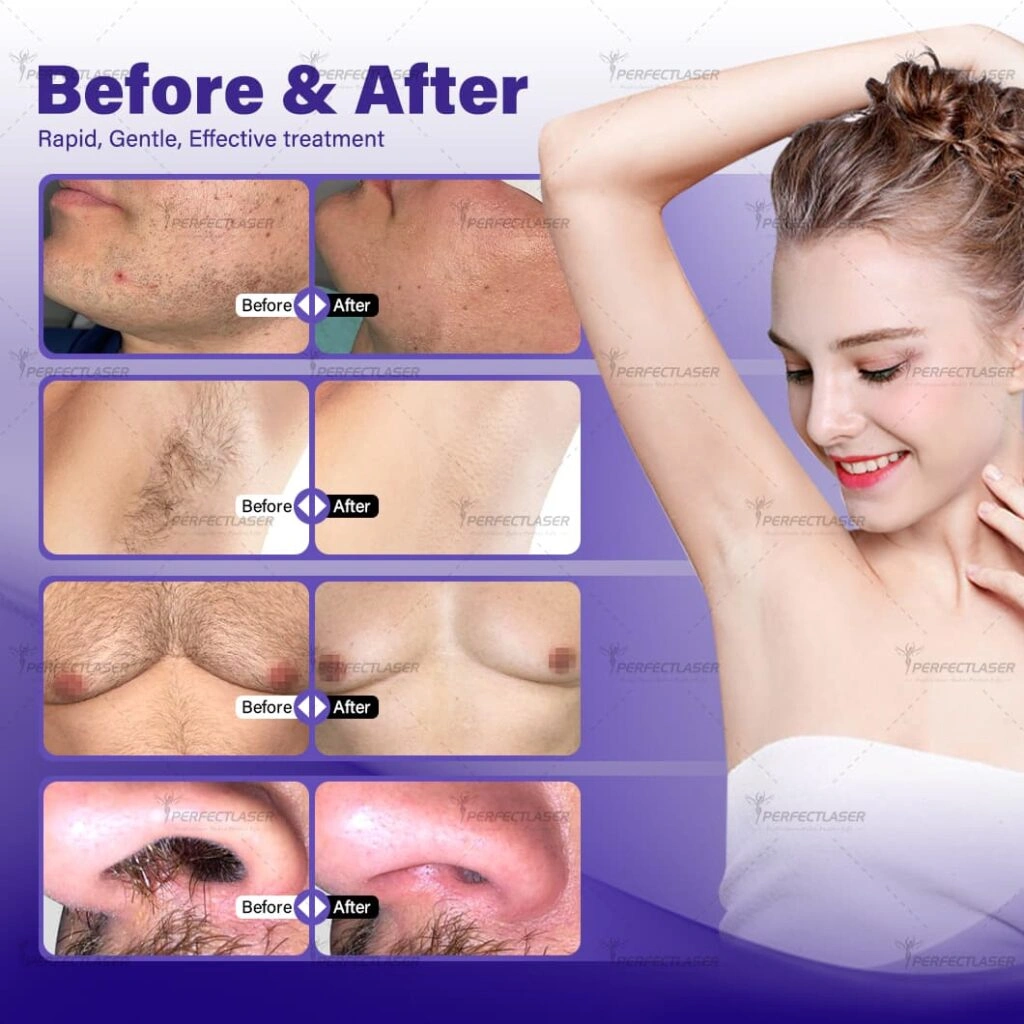

这 808nm diode laser targets melanin inside hair follicles. It removes unwanted hair well. It also keeps discomfort low. This example shows how picking the right wavelength affects how it works on the body. In beauty treatments, people choose specific wavelengths based on how tissues absorb light. For instance, 755nm suits lighter skin types. 1064nm works better for darker skin.

Still, keeping the wavelength steady can be tricky. It shifts with temperature and current changes. When temperature goes up, the bandgap gets smaller. This leads to a red shift in the light. Changes in drive current can cause slight shifts too. These happen because of heat and changes in carrier density. Top systems need to hold thermal and electrical conditions steady. This keeps the wavelength consistent.

Machines that offer several wavelengths give more options. The four wavelengths in our OEM Diode Laser Hair Removal Machine deliver great outcomes for many hair and skin tones. Combinations like 755nm+808nm+1064nm help practitioners. They can tailor treatments to fit different skin types accurately.

Power Output

Power output measures how much light energy the diode laser can provide over time. Strong power is necessary for jobs that require deep reach into tissue or coverage of big areas. This includes laser hair removal or cutting materials in industry.

便携式808nm半导体激光脱毛机 from Perfectlaser comes with a single handle. It is simple to handle and offers exact treatment. The handle provides a solid 1200W output. This machine gives quick and effective hair removal. It produces excellent outcomes for clients. This demonstrates how more power speeds up treatments and improves results.

Power output is based on the light-current (L-I) curve of the diode. Below a certain current level, no laser action happens. Above it, the output grows steadily with more current. Heat effects eventually stop further gains. If a machine can hold high power without dropping, it shows strong design.

The way it operates matters too. Continuous-wave (CW) lasers produce steady output. They suit even heating or removal tasks. Pulsed lasers give high bursts with set exposure times. In hair removal units with Diode Pulse Duration 1-400ms and Frequency 1-10Hz, these options let operators fine-tune energy. They can match skin sensitivity and the treatment zone.

Output power has to follow safety rules. Machines like the 2 IN 1 808+OPT Hair Removal Machine allow energy adjustment from 1-150J/cm². This offers flexibility to users. It also protects patients.

Cooling Design and Thermal Management

Heat control is essential to keep diode performance strong. Too much heat harms wavelength steadiness. It lowers power efficiency and cuts device life short. Poor cooling causes thermal rollover. That means a quick fall in output from high junction heat. It also leads to lasting damage from heat stress.

Our OEM Diode Laser Hair Removal Machine provides excellent power and results with two strong handles. One handle offers 1800W. The other gives 2400W. Machines like this require sophisticated cooling to stay dependable during heavy use.

Various cooling approaches are used. The choice depends on the system’s needs and power:

- Heat sinks: Simple passive method for lower power.

- Thermoelectric coolers (TEC): Active control with Peltier units.

- Liquid cooling: For strong power to move heat away fast.

- Hybrid cooling: Mixes methods for extra protection.

Cooling system: TEC+Air+Water+Semiconductor shows a layered approach. It delivers solid temperature regulation.

Many premium machines include sapphire contact cooling. SAPPHIRE COOLING -42ºC makes a pleasant contact between skin and the tip. It boosts safety and comfort for patients.

Temperature influences laser life as well. Running near suggested junction temperatures lengthens the emitter’s lifespan. It cuts down on repairs. This matters a lot in business environments. Reliable equipment directly affects earnings.

Creating top diode laser machines means finding the right balance. You need accurate wavelength, strong power, and effective cooling design. Each part helps the others. Good cooling lets high power continue. Precise wavelength ensures targeted work. Enough power makes optimized wavelengths truly effective.

Rely on our proven technology and OEM knowledge. For industrial or beauty applications, picking suitable laser diodes and dependable cooling gives performance that fits your needs.

Developers and professionals who wish to upgrade their products can benefit from expert help. It provides tips on parts selection and how to integrate systems.

常见问题解答

Q: Why is wavelength important in Diode Laser machines?

A: Wavelength controls how well the laser affects the target, like melanin in hair. Popular ones like 808nm give good depth and absorption for various skin and hair types. Steady temperature and current maintain reliable results.

Q: How does higher power output benefit Diode Laser treatments?

A: More power enables faster and deeper energy transfer. It handles big areas and coarse hair better. Based on the L-I curve, output increases past the threshold current. This raises speed and effectiveness in tasks like hair removal.

Q: Why is cooling design critical in Diode Laser machines?

A: Cooling stops excess heat. Heat can alter wavelength, cut power efficiency, and reduce diode life. Modern setups with TEC, air, water, or sapphire contact cooling hold temperatures even. They provide dependable work, comfort for patients, and safety in high-power sessions.